Dryer

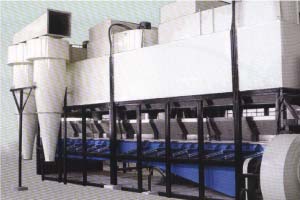

VIBRO FLUIDISED BED DRYER

Drying process

Moist fermented leaf is uniformly spread at the feed end of the perforated Grid plate through a Feed Distributor, which also works as a Ball Breaker.

The Leaf particles are fluidized on the perforated Grid plate area by the combined forces of the mechanical vibration imparted to the Grid plate - fastened on the aerodynamically designed Plenum chamber - and the velocity of the dynamic hot air forced through the specially designed perforations in the Grid plate.

The controlled level difference of fluidized bed maintained between feed and discharge end automatically develops a forward force in horizontal direction on the particles, following fluid mechanics principles.

The forward movement of tea is mainly a result of these two forces acting on the leaf particles. The drying is completed in a single pass over two-temperature zones only at a controlled rate and the correctly fired tea with high quality values is discharged from the Drier.

Vibratory Fluidized Bed Dryer (VFBD) is to-date the ultimate equipment for drying tea in the most efficient and cost effective manner, for both CTC and Orthodox varieties.

Our Suppliers